SPP 2005

The processing of cement-based building materials is the technological core in the construction and maintenance of structures. Although formability in the fresh state offers almost unlimited possibilities for shaping the structures and development of new construction techniques, today only a tiny fraction of this enormous potential is used. Lack of a scientific framework for mastering rheology-based processes is a major obstacle for developing novel and highly innovative construction technologies, such as 3D printing with concrete, as well as for solving current technical challenges, such as pumping to extreme heights.

The reason behind the shortcomings of the rheological framework is the extremely high complexity of the cementitious systems. The high chemical reactivity of mineral binders leads, only seconds after the addition of water, to changes in the particle morphology, the dissolution of larger and formation of new nanoscale particles, and severe alteration in the chemistry of the carrier liquid. Both the newly formed nanoparticles and the carrier liquid interact in turn with granular raw materials up to several centimetres in size (multiscale). Also, cementitious suspensions are always complex multi-phase systems which contain organic admixtures and air pores in addition to water and various mineral particles. Finally, casting and processing of cementitious materials are carried out under an enormous range of deformation rates, which result in extremely high demands of characterisation and simulation methods.

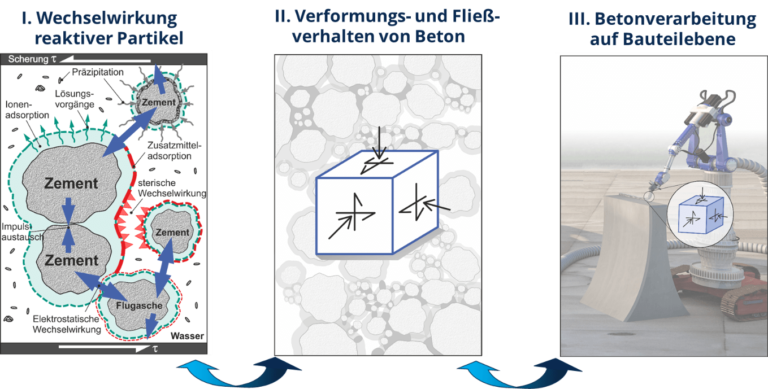

The goal of the priority program is to ascertain and describe the scientific fundamentals for understanding and consecutively designing rheology-based construction processes as well as for developing innovative, sustainable building materials and associated pioneering processing technologies. These goals are approached in a systematic scientific program that is categorized into three modules as follows:

Module I. Interaction of Reactive Particles

Research objectives are:

- Determination of force-distance relationships on particles of various type, size, shape under consideration of hydration;

- Quantification and modelling of morphological changes of binder and other fine particles as a result of hydration and/or alterations in the composition of the carrying fluid, e.g. by precipitation reactions and particle generation;

- Derivation of structure-effect relationships for prediction of the influence of superplasticizers on the particle interaction;

- Adapting numerical methods to simulate the particle interaction under consideration of electrostatic and steric effects.

Module II. Deformation Behavior of Fresh Concrete

Research objectives are:

- Modelling of macroscopic flow behavior based on particle interactions;

- Development of appropriate methods for rheology-based mix design;

- Analysis of rheology of homogeneous and locally segregated suspensions;

- Investigation of rheology of suspensions containing fibers.

Module III. Constitutive Relationships and Methods for Describing and Influencing Technological Processes

Research objectives are:

- Study of pumping behavior of suspensions under special consideration of flow-induced segregation/particle migration;

- Investigation of filling behavior of concrete in a formwork as an analogy to the open channel flow;

- Analysis of placement by means of a nozzle, e.g. spaying or 3D printing;

- Development of physically motivated, applicable test and prediction methods for rheological material behavior in specific processing scenarios.