15. Superposing particle interactions and hydration effects on the rheology of accelerated cementitious systems (SPHERE)

Principal investigator(s) – PI

- Prof. Dr. Regine von Klitzing

Technische Universität Darmstadt, Fachbereich Physik - Dr. Wolfram Schmidt

Bundesanstalt für Materialforschung und -prüfung (BAM) - Prof. Dr. Dietmar Stephan

Technische Universität Berlin, Fachgebiet Baustoffe und Bauchemie

Researcher(s) in-charge – RI

- M.Sc. Simon Becker

Technische Universität Darmstadt, Fachbereich Physik - M.Sc. Clemens Ehm

Technische Universität Berlin, Institut für Bauingenieurwesen FG Baustoffe und Bauchemie - M.Eng. Sarah Leinitz

Bundesanstalt für Materialforschung und -prüfung (BAM)

Former Members

- Dr. Zichen Lu

Technische Universität Berlin, Institut für Bauingenieurwesen

Subject Areas

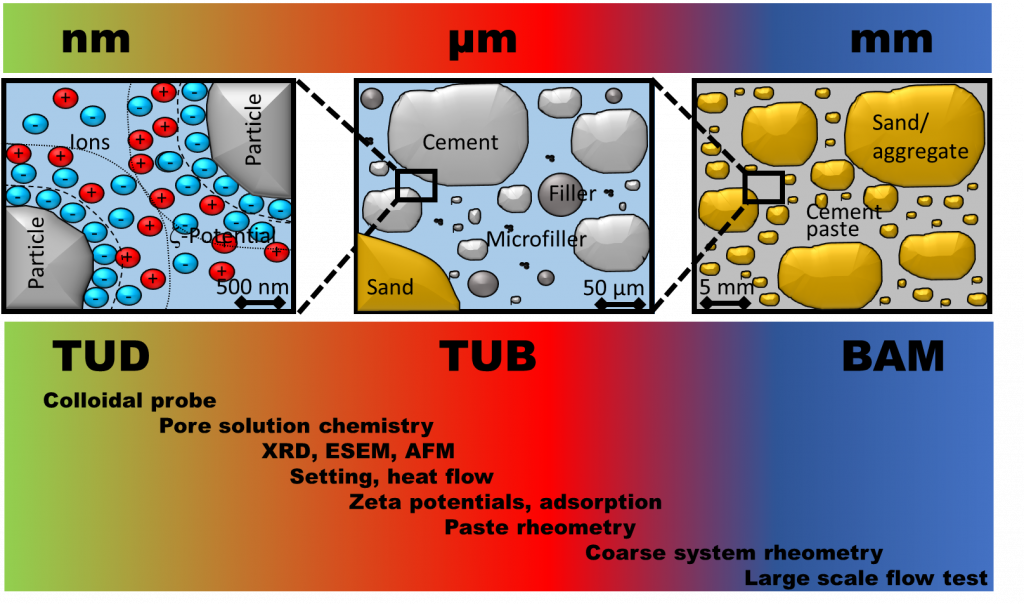

Multi-scale rheology, AFM, Accelerated hydration

Term

2018-2021

Project identifier

Deutsche Forschungsgemeinschaft (DFG) – Projekt number 387092747

Project Description

The future challenges of concrete technology demand for tailored rheological properties during the casting and early hardening process. The individual adjustment of slump retention and setting time plays a major role for technologies such as just-in-time manufacturing, target slump delivery of ready-mixed concrete, sprayed concrete, dry-mixed mortar and 3D-printing. While superplasticizers affect the rheology due to adsorption, accelerators are used to influence the hydration reaction. The employed admixtures beyond superplasticizers complicate the already complex superplasticizer effects by affecting the pore solution chemistry, as well as the morphology and interactions of the particles; depending upon the chemistry and dosage all happening within minutes. Since the effect of superplasticizers strongly depends upon the cement hydration reaction, rapid hydration causes significant rheology changes already during the casting process. A false estimation of the time dependent viscosity change can result macroscopically in improper filling, varied air pore content, poor bond, cold joint problems, inhomogeneous fibre distribution and other aspects. However, the root cause can be found on the microscopic scale in rapid changes of the ionic concentration, particle interactions, changes of the morphology and the solid volume fraction, which furthermore affect the dispersing forces between particles and the effectiveness of superplasticizers.

The SPHERE project aims at understanding the rheological effects on different dimensional scales; from mesoscopic to macroscopic. The general objective is to understand the rheology of accelerated cementitious systems during the critical steps of processing from casting until setting. In order to understand the fundamental mechanisms underlying the rheological changes, the system needs to be studied from the perspective of particle interactions as well as from hydration effects that mutually interact. Eventually, the observed effects need to be understood and evaluated on their relevance for the application level, which means an upscaling from the particle interface to the large scale concrete application has to be conducted.Direct particle interactions will mainly be studied using atomic force microscopy in various conditions on simplified model systems. The results will support understanding changes of rheological phenomena induced by changes in the pore solution chemistry as well as by adsorption of ions and polymers on particle surfaces. Effects of changed morphology and phase evolutions will be studied using XRD techniques, SEM, AFM, US, DTA, etc. The rheological response will be examined on various scales from solution level up to paste, mortar and concrete rheometry as well as by using applied technologies such as spraying, large scale casting and standard fresh concrete technologies.

Publications

Colloids and Surfaces A: Physicochemical and Engineering Aspects 575 (2019)

in: V. Mechtcherine, K. H. Khayat, E. Secrieru (Eds.), Rheology and Processing of Construction Materials, pp. 106-115 (2019)

in: V. Mechtcherine, K. H. Khayat, E. Secrieru (Eds.), Rheology and Processing of Construction Materials, pp. 571–579 (2019)

in: V. Mechtcherine, K. H. Khayat, E. Secrieru (Eds.), Rheology and Processing of Construction Materials, pp. 602–609 (2019)

in: V. Mechtcherine, K. H. Khayat, E. Secrieru (Eds.), Rheology and Processing of Construction Materials, pp. 619–627 (2019)

Data in Brief 27 (2019)

Data in Brief 30 (2020)

Materials and Structures 53 (2020)

Materials 13 (7) (2020)