28. Effects of steel and polymer fiber on the rheological behavior and processing parameters of cement-based materials in the context of 3D-printing by layered extrusion – printFRC

Principal investigator(s) – PI

- Prof. Dr.-Ing. Viktor Mechtcherine

Technische Universität Dresden, Institut für Baustoffe

Researcher(s) in-charge – RI

- Dipl.-Ing. Silvia Reißig

Technische Universität Dresden, Institut für Baustoffe

Researcher(s) associated – RA

- M.Sc. Egor Ivaniuk

Technische Universität Dresden, Institut für Baustoffe

Subject Areas

Construction Material Sciences, Chemistry, Building Physics

Term

Since 2021

Project identifier

Deutsche Forschungsgemeinschaft (DFG) – Projektnummer 387152958

Project Description

The purposeful digitalization and automation of construction processes, e.g. using additive manufacturing, appears to be the only feasible solution in mastering the severe problems resulting from low productivity and increasing shortages of skilled labor. The experimental, theoretical, and numerical work within the previous SPP 2005 project at the TU Dresden brought numerous new insights with respect to the effects of aggregates on both the dynamic and static rheological properties of printable concretes and subsequently on both of the key process characteristics of layered extrusion – extrudability and buildability.

This follow-up project focuses on the fundamentals required on the purposeful integration of fiber reinforcement into additive manufacturing by layered extrusion. The main objective is the full, quantitative description of the effects of fiber on rheological properties of printable fiber-reinforced concrete (PFRC) in its fresh state. Furthermore, the underlying mechanisms of the fibers’ influences on the processing parameters extrudability and buildability are to be investigated experimentally and numerically. Novel experimental methodologies and an enhanced DEM model for characterizing PFRC and its processing are to be developed. The project deliveries should enable a thoroughgoing estimation of extrusion behavior and shape stability after deposition, indeed for various processing scenarios based on PFRC composition and the rheological parameters of constitutive pastes.

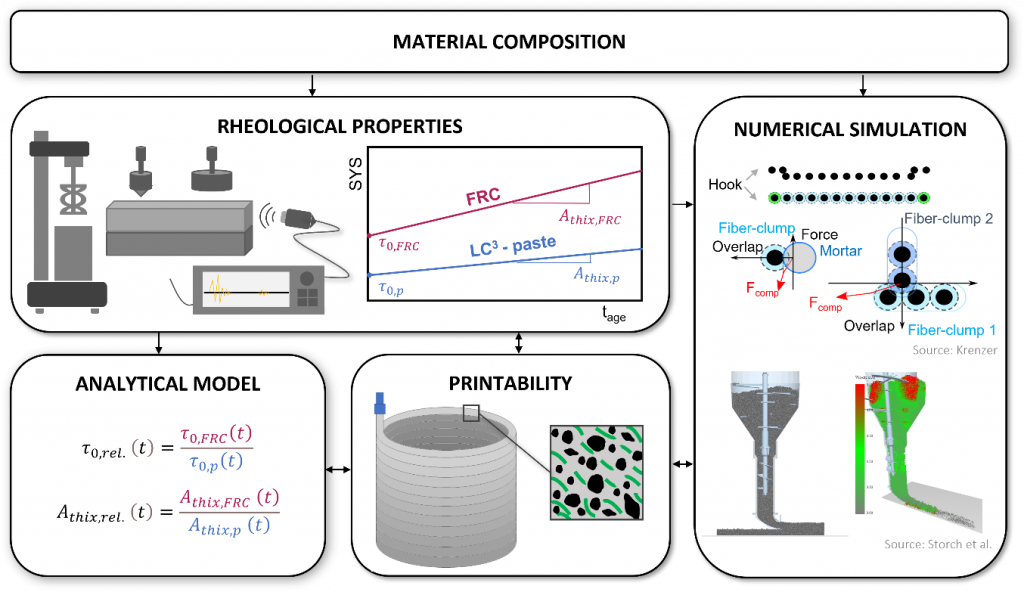

The research program is divided into three segments: Materials and Rheology, 3D printing and Simulations.

In the first project segment the characteristics of concrete’s constituents which are likely to influence rheological properties and processing parameters will be experimentally determined and the mix design for PFRC will be established. Two types of thixotropic, sustainable LC³ printable concrete will be investigated, a coarse-grained composition with rigid steel fiber and a fine-grained composition containing flexible polymer microfiber. Furthermore, the research focuses on the effects of fiber characteristics and volume fraction on both the dynamic and static rheological properties of PFRC. Static rheological properties will be investigated by means of constant shear rate test (CSR) using a Viskomat XL rheometer. Also, uniaxial compression test, ultrasonic measurement and penetration test will be performed to study the static rheological properties of PFRC under consideration of its time-dependent behavior. On this basis, analytical models will be formulated to describe the effect both of rigid and of flexible fiber on the static rheological properties of PFRC under consideration of its time-dependent behavior. Additionally, a novel methodology for a penetration test for in-situ conditions will be developed to evaluate changes in static yield stress over time for PFRC containing coarse aggregates using both experimental and numerical approaches.

The project segment 3D Printing focuses on the AC-related properties and the effects of steel and polymer fiber characteristics and volume fraction on the extrudability and buildability of PFRC – including appropriate on-line and off-line methods to characterize quantitatively the process-induced fiber orientation and distribution. Correlations among the dynamic rheological properties and extrudability, and between the static rheological properties and buildability of PFRC, are to be established.

Finally, in the last project segment Simulation, a DEM model for PFRC is to be developed using customized algorithms for incorporating different types of fiber, or their effects, with minimal computational resources. The developed discretization algorithms and contact models will be used for numerical simulations of the extrusion process, deposition of layers, compression tests, and the buildability of PFRC. Additionally, DEM simulations of a penetration test will be performed to facilitate the development of the test’s methodology.

A graphic depicting the structure and objectives of the project