3. Analysis of Time-variant Nano- and Microscopic Mechanisms for Modelling the Meso- and Macroscopic Segregation Stability of Concrete Subject to Vibration

Principal investigator(s) – PI

- Professor Dr. rer. Nat. Nadja-Carola Bigall

Leibniz Universität Hannover, Institut für Physikalische Chemie und Elektrochemie

Researcher(s) in charge – RI

- M.Sc. Patrick André Kißling

Leibniz Universität Hannover, Institut für Physikalische Chemie und Elektrochemie - M.Sc. Tabea von Bronk

Leibniz Universität Hannover, Institut für Baustoffe

Associated researcher – AR

- Professor Dr.-ing. Ludger Lohaus (PI)

Leibniz Universität Hannover, Institut für Baustoffe

Subject Area

Construction Material Sciences, Chemistry, Building Physics

Term

2018-2021

Project Identifier

Deutsche Forschungsgemeinschaft (DFG) – Projekt number 387093558

Project Description

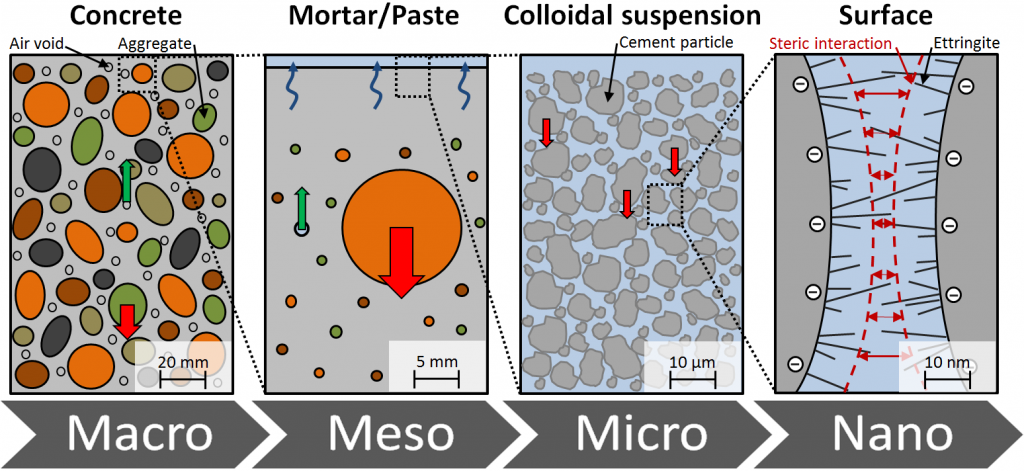

Innovative processing techniques in concrete construction, such as 3D printing or modern and filigree concrete structures, place high demands on the workability of the concrete used. In general, the trend in concrete construction is always towards softer and more flowable concrete. However, the flowability and the stability of a concrete represent competing demands, because the use of flowable concrete increases the risk of unintentional separation. The flow behaviour of the concrete and the meso and macroscopic forms of segregation (deaeration, sedimentation, water secretion) in fresh concrete structures, caused by external forces such as gravity, pump pressure or vibration energy, constitute rheology-based processes. The rheological behaviour can be described by the interactions between the continuous (liquid) and the dispersed (solid) phase which are dependent on the partially nanoscale particle morphology, the particle interactions and the chemical properties of the continuous phase. In addition, an interaction with granular aggregates occurs, which has an effect on the macroscopic level. The existing model approaches for describing the load-deformation behaviour for cementitious suspensions represent a promising basis. However, these do not take into account the influence of early-accumulating hydration products from the microstructure. For a description of the load-deformation behaviour and the stability, existing modelling approaches have to be extended by the plastic component, determined by the mechanical behaviour of early hydration products.The identification of the correlations between the properties on the nano- and microscale and the measurable rheological properties as a function of time represents the basis of this proposal. The particle morphology and the physical and electrochemical properties of the carrier fluid at defined times after the addition of water are to be determined analytically. In addition, how these nano- and microscopic characteristics affect measurable rheological properties of the binder suspension will be investigated. A high shear stress, as occurs during concrete casting during vibration effects, results in a significant change in the rheological properties of the paste phase that will be represented via the description of the structural breakdown behaviour of the suspension. Besides the resulting influence of the properties of the paste phase itself, it particularly influences the interaction between the paste phase and the intergranular particles (aggregates). This interaction will be identified during exemplary mortar and concrete investigations by varying the granulometric properties of the aggregate and by varying the structure of the graduation curve. Thanks to this implementation of the multiscale structure of the work programme, all relevant factors will be identified and will serve as input variables in a conceptual model to describe the segregation stability of concrete during vibration effects.

Multiscale and multiphase approach of fresh concrete

Publications

in: V. Mechtcherine, K. H. Khayat, E. Secrieru (Eds.), Rheology and Processing of Construction Materials, pp. 610–618 (2019)