27. Viscoelasticity related deformability and structural build-up of fresh concrete – Effects of the carrier liquid chemistry on particle interactions (VisCodeBuild)

Principal investigator(s) – PI

- Dr. Wolfram Schmidt

BAM – Berlin, Bundesanstalt für Materialforschung und -prüfung - Dr.-Ing. Neven Ukrainczyk

TU Darmstadt, Werktoffe im Bauwesen - Dr.-Ing. Thomas Kränkel

Technische Universität München, Lehrstuhl für Werkstoffe und Werkstoffprüfung im Bauwesen – cbm

Researcher(s) in-charge – RI

- M.Eng. Mareike Thiedeitz

Technische Universität München, Lehrstuhl für Werkstoffe und Werkstoffprüfung im Bauwesen – cbm - M.Eng. Sarah Leinitz

BAM – Berlin, Bundesanstalt für Materialforschung und -prüfung

Researcher(s) associated – RA

- Dr. Alexander Mezhov

BAM – Berlin, Bundesanstalt für Materialforschung und -prüfung

Subject Areas

Construction Material Sciences, Chemistry, Building Physics

Term

Since 2021

Project identifier

Deutsche Forschungsgemeinschaft (DFG) – Projektnummer 451894070

Project Description

The significant CO2 footprint of cement can be reduced considerably through substitution of clinker with pozzolanic materials. Calcined clays (CCs) are considered as the most promising substitution material, however, depending on the composition of the natural raw clay which always presents a mixture of different clay minerals, various effects can occur in cement, this study aims to self-prepare four different calcined clays (meta kaoline, meta montmorillonite, meta illite and meta muscovite) of high pozzolanic activity via calcination, to characterize them and to evaluate their impact on the rheology of suspensions of these pristine clays or OPC-CC 70:30 blends. Furthermore, the calcined clay blended cement provided by the Central Project will be included as a reference material in all tests.

By using a Couette-type rotational viscometer, especially their shear-dependent viscosity will be determined and corresponding rheological key parameters such as plastic and apparent viscosity, yield stress, gel strengths etc. will be captured and the overall behavior of the fluid (shear-thinning or shear-thickening) shall be ascertained. Moreover, the rheograms will be fitted to known rheological models including Power law, Bingham, Herschel-Bulkley etc.

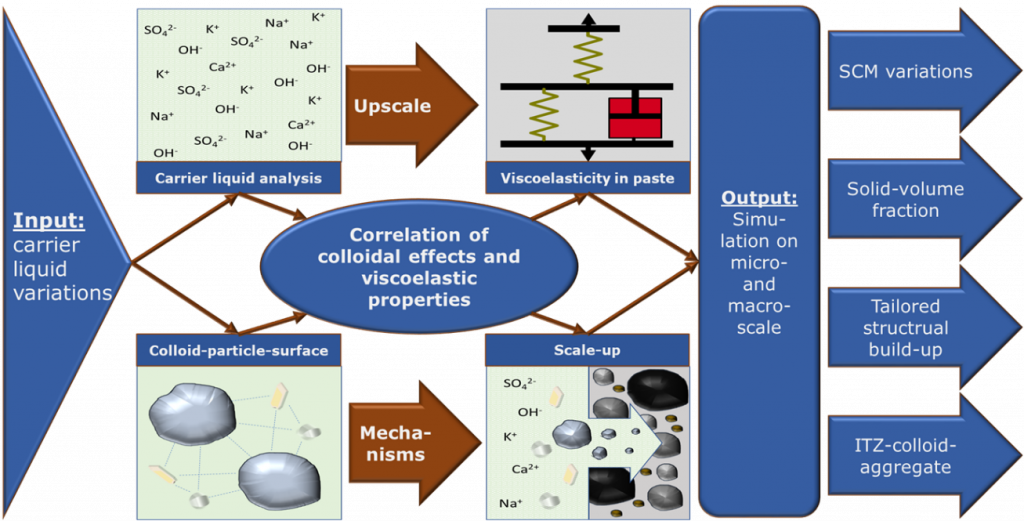

Carrier liquid investigations and the interparticle interactions between colloidal and particle surfaces serve as basis for describing viscoelastic properties at micro scale, which will provide input parameters for flowability simulations on the macro scale

The second funding period builds further on that and aims at achieving fundamental understanding of the viscoelastic behavior of concrete, by particularly focusing on the impact of surface and colloidal physico-chemical aspects. With the new project partner BAM, the ionic concentration of the carrier liquid evolution will be explicitly considered, and in its rheological response to chemical and interfacial characteristics of solids (colloids, particles, hydrates) and the subsequent evaluation of phase interactions (liquid, colloid, particle, hydrate, polymer) over the course of initial hydration. These results will allow to evaluate correlations of the colloidal chemistry with the viscoelastic deformation parameters of cementitious pastes measured with oscillatory rheometry, followed by correlations with the viscoelastic flow parameters measured with rotational rheometry. A special rheometric setup that allows for in situ observation of the effect of colloidal interactions within the liquid phase of cementitious pastes with optical and spectroscopic methods under different shear conditions (SAOS, LAOS, rotational, normal force) will therefore be employed.

Results of the colloidal phase chemistry evolution will further be implemented in particle based microstructural models (statistical and full 3D) to simulate and predict the rheological behavior (i.e. yield stress and structural build-up) of cementitious pastes during rest and low shear. This will serve as input for an advanced computational fluid dynamics (CFD) model to simulate concrete flow (i.e. form filling ability), while accounting for the evolution of the time- and shear dependencies on the viscoelastic deformation and the impact of the chemical particle interactions within the cementitious paste.

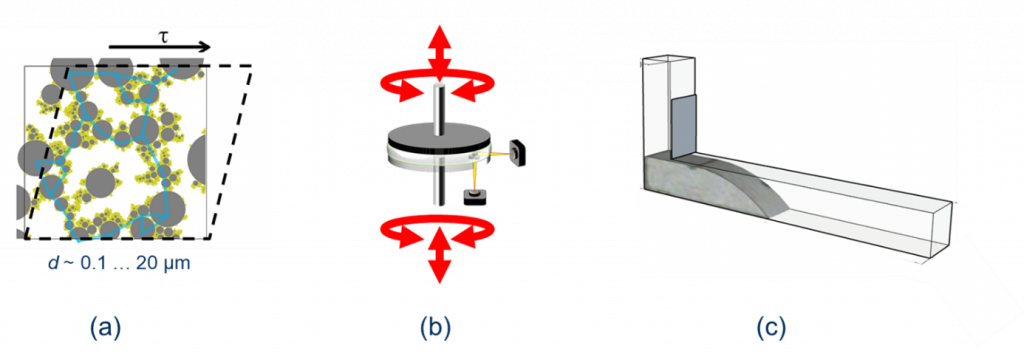

Multi-scale investigations of cementitious building materials from (a) nano-to-micro scale analytical investigations and particle modeling, (b) micro-scale, in-situ combined rheological analysis of cementitious paste systems and (c) flowability and CFD simulations of cementitious pastes and concrete on the macro-scale

Experimental upscaling from paste to concrete systems, including various sand and coarse (recycled) aggregates will be conducted, and the relevance of colloidal interactions in the presence of overlapping macroscopic rheological influences through rotational rheometry and empirical flow and stoppage tests (form-filling tests) will be evaluated. Experimental results will be further used to validate flow predictions received from upscaled models using CFD simulations.

Publications

Materials 14 (19) (2021)

Wissenschaftlicher Kurzbericht 60 (2021)

Materials 15 (1) (2022)

M. Thiedeitz, T. Kränkel, C. Gehlen

Rheologica Acta 61 (2022)