6. Form filling ability of fresh concrete: A time and hydration dependent approach

Principal investigator(s) – PI

- Professor Dr.-Ing. Christoph Gehlen

Technische Universität München, Zentrum für Baustoffe und Materialprüfung - Professor Dr.ir. Eduardus A.B. Koenders

Technische Universität Darmstadt, Institut für Werkstoffe im Bauwesen

Researcher(s) in charge – RI

- Dr. Antonio Caggiano

TU Darmstadt, Werktoffe im Bauwesen - Dr. Ing. Dott. Mag. Albrecht Gilka-Bötzow

Technische Universität Darmstadt, Institut für Werkstoffe im Bauwesen - M.Sc. Shahla Shamorahdi

Technische Universität Darmstadt, Institut für Werkstoffe im Bauwesen - M.Eng Mareike Thiedeitz

Technische Universität München, Centrum für Baustoffe und Materialprüfung - Dr. Ing. Neven Ukrainczyk

Technische Universität Darmstadt, Institut für Werkstoffe im Bauwesen

Associated researcher – AR

- Dr. Ing. Thomas Kränkel

Technische Universität München, Centrum für Baustoffe und Materialprüfung

Subject Area

Construction Material Sciences, Concrete Rheology, Numerical Modeling

Term

2018-2021

Project Identifier

Deutsche Forschungsgemeinschaft (DFG) – Projekt number 387065993

Project Description

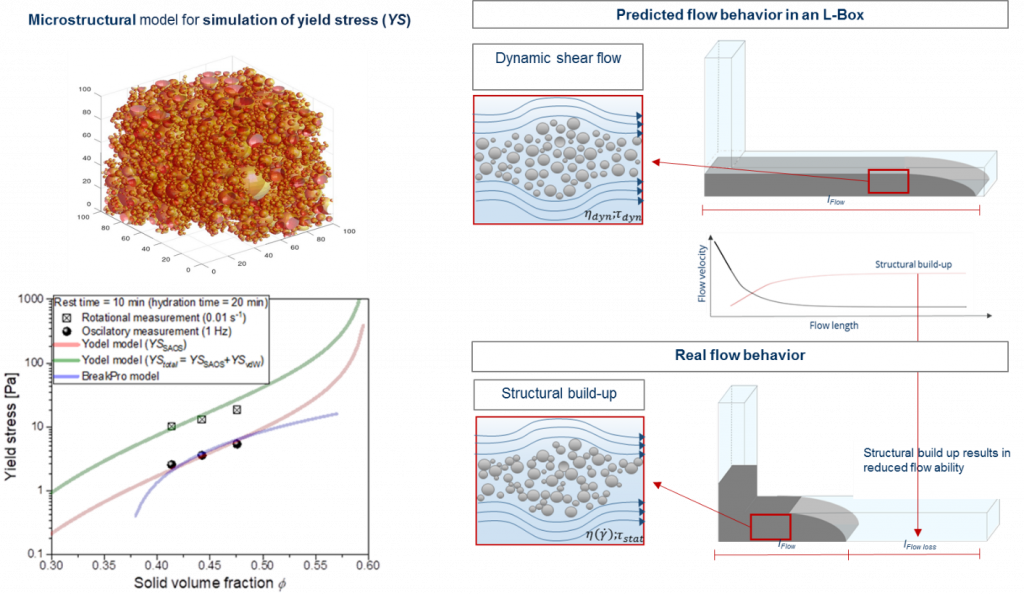

The project partners TU Munich (TUM) and TU Darmstadt (TUDa) investigate the flowability and workability of cementitious pastes, mortar and concrete, emphasizing the dependence of the structural

build-up within a cementitious paste with time, as the tandem project “Form Filling ability of fresh concrete – a time and hydration dependent approach”. Outgoing from the rheological investigation, the project aims to provide a numerical simulation of both the microstructural rheological behavior of cement pastes on the micro scale and the form filling ability on the macro scale. Virtual microstructures are generated using particle algorithms for cement flocculation and boundary nucleation. Morphological outputs are used to feed a statistical yield stress model, which is based on interparticle bonds Breaking Probability, thus named BreakPro. The BreakPro model is correlated with the actual yield stress of a cementitious suspension. Changes of the rheological behavior on micro scale due to nucleation and flocculation effects with time or shear-dependent deflocculation are considered. Thus, the BreakPro model can be taken as input simulation for further macro modeling of formfilling behavior of cement, mortar and concrete. The macro modeling, conducted by computational fluid dynamics (CFD) considers both micro- and macrostructural material properties. For a fundamental structural rheological knowledge, the project partners investigate the rheological behavior of various cementitious suspensions and concretes with respect to a reference mix specified in the SPP central project. Rheological parameters are investigated using various rheological procedures and geometries for both microscopic investigation of changes in viscoelastic material properties due to shear- and hydration dependent structural build-up or break-down and macroscopic dynamic rheological parameters. Viscoelastic properties need to be investigated on a much smaller fundamental physical and chemical scale level in order to be able to better understand their effect on the rheology of modern concretes, especially those containing large quantities of supplementary cementitious materials (SCMs). A clear scientific understanding of the time and shear dependent evolution of viscoelasticity is key, especially with regard to the effect of the complex physico-chemical particle interactions on the flowability and form filling behavior of concrete. By suitable adjustment of the mixture composition, only one rheological parameter at a time is varied. This approach enables the quantification of the effect of material characteristics on the rheological parameters which can afterwards be implemented in a rheological model. In order to verify the rheological model both with the BreakPro model and CFD, the rheological measurements are accompanied by investigations of the form filling ability of mortar and concrete in L-shaped model formworks. The rheological model is finally implemented in computational fluid dynamics (CFD). Finally, rheological parameters computed by microstructural modeling can be upscaled as input parameters for CFD modeling of form filling and compared with corresponding test results. The project thus combines the two fields of expertise of the two project partners, i.e. TUM: experimental determination of rheological parameters of cementitious pastes, mortars and concrete using highly-sensitive rheometry, and TUDa: microstructural modelling of paste systems.

Microstructural and macroscopic rheological behavior of cementitious pastes

Publications

in: A. Mandić Ivanković, M. Kušter Marić, A. Strauss, T. Kišiček (Eds.), International Conference on Sustainable Materials, Systems and Structures (SMSS 2019), pp. 272-279 (2019)

in: V. Mechtcherine, K. H. Khayat, E. Secrieru (Eds.), Rheology and Processing of Construction Materials, pp. 273–280 (2019)

Materials 12 (18) (2019)

N. Ukrainczyk, A. Caggiano, D. S. Schicchi, A. Gilka-Bötzow, E. Koenders

in: V. Mechtcherine, K. H. Khayat, E. Secrieru (Eds.), Rheology and Processing of Construction Materials, pp. 636–643 (2019)

Materials and Structures 53 (2020)

Materials 13 (7) (2020)

Materials 13 (9) (2020)

Materials 13 (12) (2020)