13. Investigating the Rheological Behavior of Low Water-to-Cement Concretes Admixed With Superplasticizers and Co-Dispersants and the Underlying Dispersion Mechanism

Principal investigator(s) – PI

- Prof. Dr. Johann Plank

Technische Universität München (TUM), Lehrstuhl für Bauchemie

Researcher(s) in-charge – RI

- M.Sc. Manuel Ilg

Technische Universität München (TUM), Lehrstuhl für Bauchemie

Associated researcher – AR

- Dr. Lei Lei

Technische Universität München (TUM), Lehrstuhl für Bauchemie

Subject Area

Construction Material Sciences, Chemistry, Building Physics

Term

2017-2021

Project identifier

Deutsche Forschungsgemeinschaft (DFG) – Projekt number 387082770

Project Description

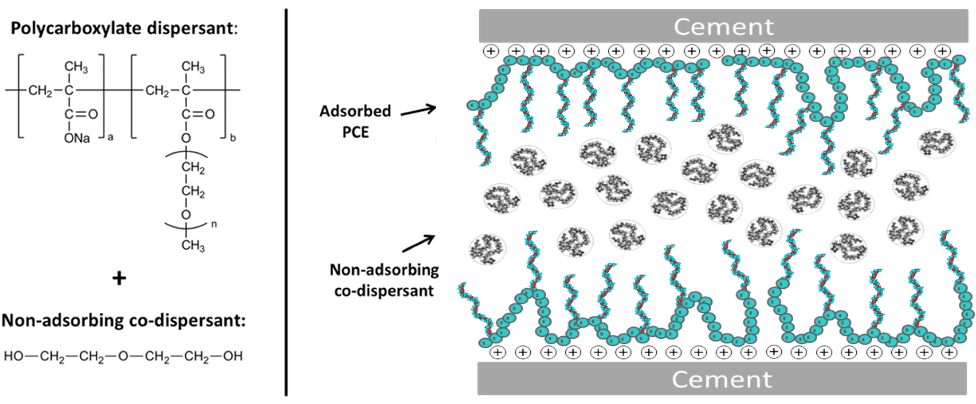

Concretes formulated at very low w/c ratios (< 0.30) have become increasingly popular. However, applicators often report a honey-like “sticky” consistency for those concretes which creep rather than flow and exhibit a low speed of flow when poured at the job site. Such rheological behavior is highly undesirable for the placement process. The aim of the project was to ascertain the main causes for the stickiness and creeping flow behavior of concretes of low w/c ratios and to provide potential solutions to overcome such unfavorable rheological properties. Regarding this, specific structural motifs for PCE superplasticizers were identified which favor a high speed of flow. Additionally, non-ionic co-dispersants were tested as flow enhancers and the working mechanism underlying this new type of dispersion were investigated in more detail by using different experimental techniques (e.g. dynamic light scattering, critical micelle concentration etc.).The overall goal of this project was to significantly deepen the knowledge on the dispersion mechanisms occurring specifically in low w/c systems, and to interconnect the data obtained for the adsorbed layer thickness, HLB values and structural motifs of individual PCE molecules with key rheological parameters such as yield stress, plastic viscosity and flow speed.

Conceptual sketch illustrating the working mechanism of the non-adsorbing co-dispersants in cement at low w/c ratios

Publications

in: V. Mechtcherine, K. H. Khayat, E. Secrieru (Eds.), Rheology and Processing of Construction Materials, pp. 134-141 (2019)

Colloids and Surfaces A: Physicochemical and Engineering Aspects 587 (2019)

Data in Brief 27 (2019)

Construction and Building Materials 258 (2020)

Construction and Building Materials 259 (2020)

Data in Brief 30 (2020)

Data in Brief 31 (2020)