14. Understanding fresh concrete flow by advanced rheological characterization

Principal investigator(s) – PI

- Prof. Dr.-Ing. Hans-Joachim Schmid

Paderborn University

Researcher(s) in-charge – RI

- M.Sc. Sebastian Pawelczyk

Paderborn University

Associated researcher – AR

- Dr.-Ing. Steffen Jesinghausen

Paderborn University

Subject Area

Construction Material Sciences, Chemistry, Building Physics

Term

2017-2021

Project identifier

Deutsche Forschungsgemeinschaft (DFG) – Projekt number 403524381

Project Description

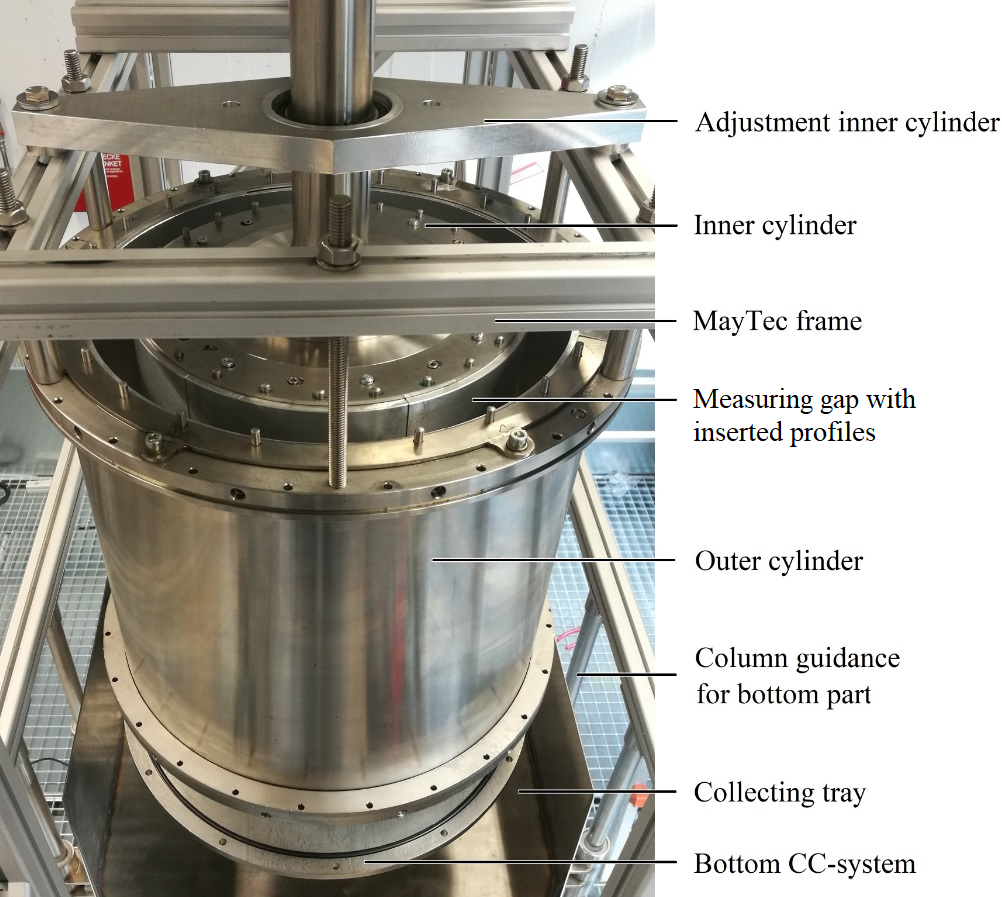

The overall objective of this project proposal is to significantly enhance the fundamental understanding of the flow behaviour of fresh concrete. Therefore, it aims to perform a rheological characterization of concrete including particle sizes up to the centimetre scale. Today, profound rheological measurement methods are only available for cement pastes and to a limited extent for mortar. For concrete, only ‘relative’ characterization methods are available, i.e. allowing only a qualitative comparison of different types of concrete. In contrast, this project aims for ‘absolute’ measurements, i.e. delivering rheological properties of concrete, which are transferable and can be used directly for simulation of concrete flow in arbitrary geometries. To achieve this, an appropriate coaxial concrete rheometer will be developed and built. It will be equipped with a movable non-interfering ultrasonic image velocimetry (UIV) system for on-line monitoring of the flow profile or even the particle distribution during measurements. This system will allow for real rheological measurements, which offer unbiased, measurement system independent rheological parameters and flow curves while the validity of the system is checked in-situ. Since wall slip is a fundamental problem for all concrete rheometers, different 3D-printed wall geometries will be analysed and improved for the best possible results. It is expected to find different geometries for different concrete compositions. In addition, comparative measurements of the different concrete phases – cement, mortar and concrete – will be carried out. This aims to understand the influence of the coarse grains on the rheology of concrete. Since simulations are often based on flow properties of the cement phase only, these measurements will help to understand current problems and limitations in simulations and acquire a more profound understanding of concrete flow in general. Furthermore, the rheometer will be used to evaluate the performance of different simulation methods of other members in the priority program. The rheometer can be used for all 3 phases of common concrete suspensions, i.e. cement, mortar and concrete, and provides measured flow/concentration profiles via UIV. Therefore, experimental data will allow for detailed comparison with simulations. This should lead to a validation of simulation models and a precise calibration of model parameters. Finally, comparative measurements with classical (i.e. ‘relative’) concrete viscometers will be performed. Combined with UIV measurements and simulations this will allow for a better understanding of the phenomena occurring in these classical set-ups. Thus, experimental data gained with the new rheometer can even help to implement new model based evaluation methods to improve data interpretation from classical viscometers.

Coaxial Measuring cell with rotating bottom plate for DIN/ISO compliant measurements for suspensions with particle sizes up to the centimeter range while maintaining a reasonable size

Publications

Materials and Structures 53 (2020)

Materials 13 (2)